Data-driven manufacturing implies that decisions controlling the manufacturing process should be based on facts, not guesses, wishes, theories or opinions. Emerging technology is enabling both people and equipment to collect and process the facts they need to achieve better results. Driving manufacturing with data promotes integration and coherence across manufacturing organizations throughout the supply chain.

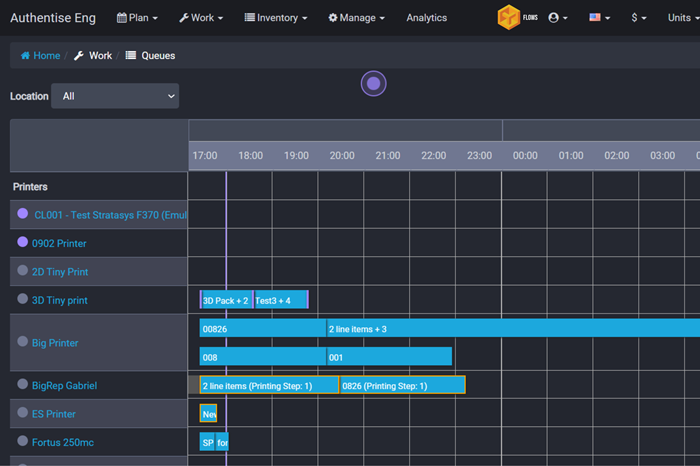

How to Grow the Business with Real-Time Job Status Data

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

Data-Driven Manufacturing: Essential Reading

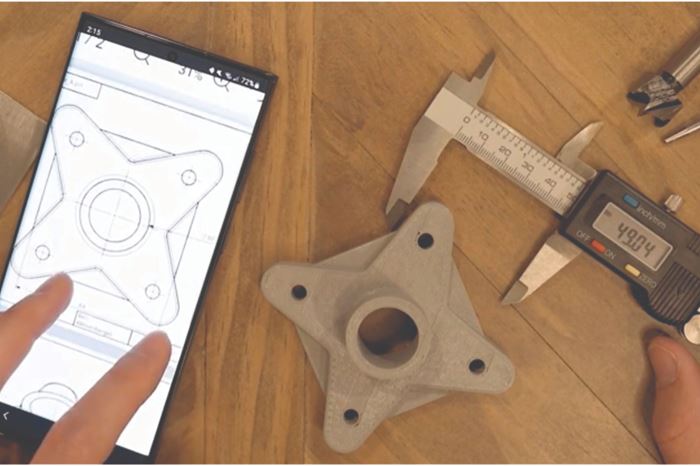

Bluetooth-Enabled Digital Readout System

IMTS22: The interface of the droPWR system enables connection to multiple machine configurations in one tablet, including for milling, turning and grinding machines with up to six axes.

Automation and Connectivity Features Boost Machine Data Platform Efficacy

IMTS22: Expanded features from MachineMetrics are intended to enable manufacturers to drive frontline worker productivity and factory systems with real-time machine data.

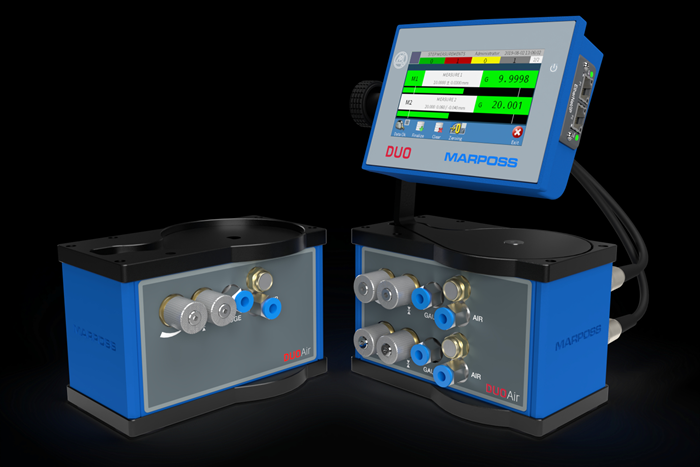

Data Collection Software Increases Efficiency, Reduces Downtime

IMTS22: Wintriss Controls Group’s upgraded ShopFloorConnect identifies and quantifies excessive production losses and bottlenecks.

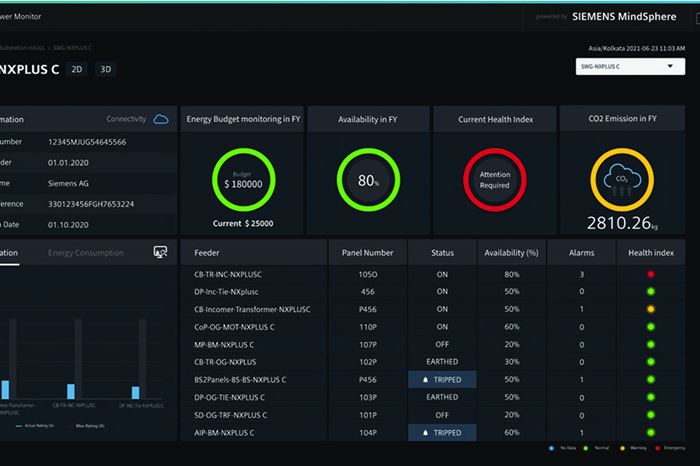

Predictive Maintenance Software Offers Real-Time Visibility

IMTS22: Vimana’s predictive maintenance software collects and transforms large volumes of data from multiple sources, including sensors, machine data, manufacturing and IT systems.

Automated Production Intelligence Streamlines Monitoring

IMTS22: Datanomix’s Automated Production Intelligence platform provides automated job performance data for every single part made on every machine, with no configuration.

FAQ: Data-Driven Manufacturing

How do you choose an ERP system for a data-driven machine shop?

- Consider your objectives and requirements.

- Measure return on investment (ROI).

- Speak to fellow ERP users.

- Scrutinize the demo.

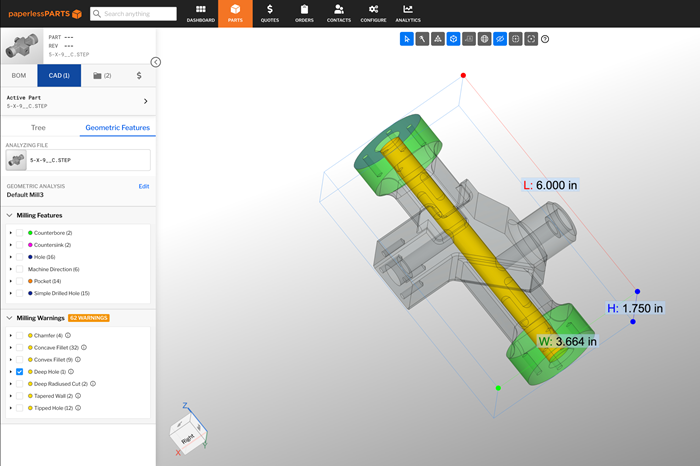

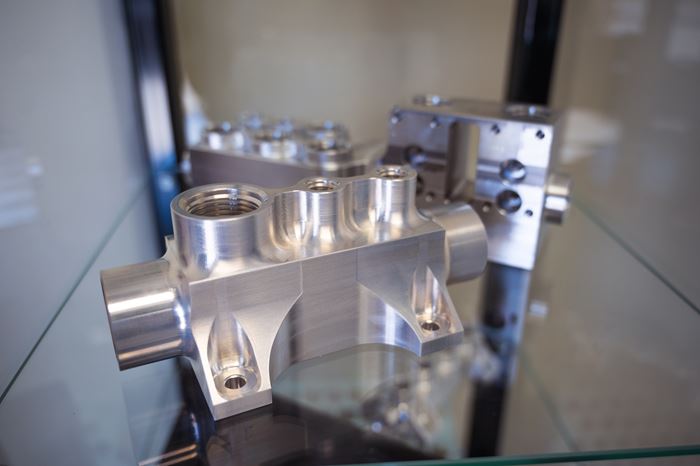

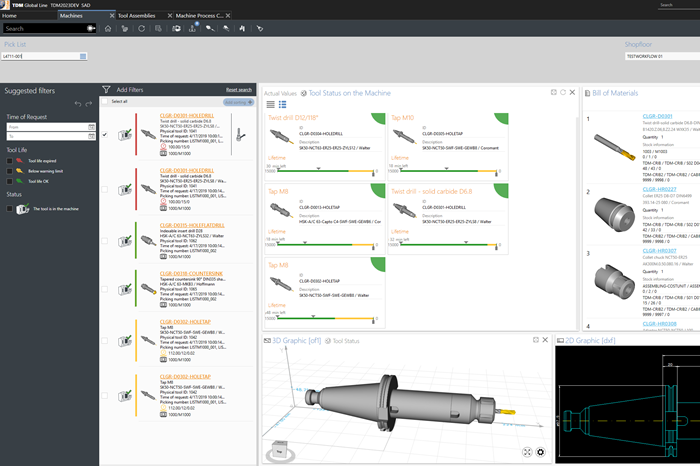

How does “tag and track” technology keep data chains intact?

- Streamlining workflow.

- Automating and verifying tool setups.

- Managing the tool crib.

- Reducing waste through productivity improvement.

What are some of the best practices for manufacturing cybersecurity?

- Training regularly

- Requiring strong passwords

- Requiring multi-factor authentication

- Monitoring for threats

- Consider security beyond virtual security

Data-Driven Manufacturing Suppliers

Narrow by Data-Driven Manufacturing Category

- Calibration Software

- ERP for Make-to-Order Manufacturing

- ERP for Standard Products Manufacturing

- Job Estimating Software

- Manufacturing Execution Systems (MES)

- Quality Documentation Software

- Software, Accounting/General Ledger/Payroll

- Software, Database Management

- Software, Other Manufacturing

- Statistical Data Collection & Analysis Software

- Tool Crib Control Software

- Software, CAD/CAM

- Software, CAD/CAM for Additive Manufacturing

- Software, Engineering Analysis & Simulation

- Software, Machinability Databases

- Software, NC Program Optimization

- Software, NC Verification

- Software, Nesting

- Software, Post Processors, Stand-Alone (Sold Independent of CAM System)

- Software, Tool Design

- Robot Controllers

- Programmable Logic Controls (PLC)

- Memory Units

- Machine Monitoring Systems

- Identification Systems

- Direct or Distributive Numerical Control (DNC) Systems

- Digitizing/Scanning Systems

- Digital Readout (DRO) Units

- Computer Numerical Control (CNC) Units

- Computer Numerical Control (CNC) Software (Sold Independent of Hardware)

- Communications Networks & Data Transmission Equipment

Diving Deeper Into Machine Monitoring Data

Data visualization is the first step in using machine monitoring data, but taking it to the next level requires looking for trends within the data.

Don't Miss This: Technology Trends

Manufacturing advances like automation and machine monitoring software are not only affordable for job shops, they may soon become competitive necessities.

#imts

Bluetooth-Enabled Digital Readout System

IMTS22: The interface of the droPWR system enables connection to multiple machine configurations in one tablet, including for milling, turning and grinding machines with up to six axes.

#imts

Automation and Connectivity Features Boost Machine Data Platform Efficacy

IMTS22: Expanded features from MachineMetrics are intended to enable manufacturers to drive frontline worker productivity and factory systems with real-time machine data.

#imts

Data Collection Software Increases Efficiency, Reduces Downtime

IMTS22: Wintriss Controls Group’s upgraded ShopFloorConnect identifies and quantifies excessive production losses and bottlenecks.

#imts

Predictive Maintenance Software Offers Real-Time Visibility

IMTS22: Vimana’s predictive maintenance software collects and transforms large volumes of data from multiple sources, including sensors, machine data, manufacturing and IT systems.

#imts

Automated Production Intelligence Streamlines Monitoring

IMTS22: Datanomix’s Automated Production Intelligence platform provides automated job performance data for every single part made on every machine, with no configuration.

#imts